In late September, a slew of Chinese investment was announced for battery material production in Morocco. Chinese mid-stream giant, CNGR, announced plans to construct a NMC and LFP precursor material plant; while Chinese mining major, Huayou Cobalt, and South Korean cathode and cell manufacturer, LG Chem, signed a non-binding MoU for the construction of a LFP cathode plant and a lithium refinery.

Author Cameron Hughes

Battery Market Analyst View profile

Contributor Sam Adham

Head of Battery Materials View profile

CNGR has formed a joint venture with Al Mada, a Moroccan private investment fund, to construct the precursor plants in El Jadida region, Morocco. Phase 1 of the project is anticipated to have a nameplate capacity of 120,000 t/y of NMC precursor and 60,000 t/y of LFP precursor, as well as 30,000 t/y of recycled battery material.

The $2 bn project is anticipated to begin construction in 2023, with initial production planned for 2025. Upon completion, the plants are expected to feed the European and North American battery markets.

CNGR continues to expand its role in the battery value chain through overseas investments. In June 2023, the company announced its first ex. China cathode and precursor venture, a $1.2 bn precursor plant in Pohang, South Korea with steel giant POSCO.

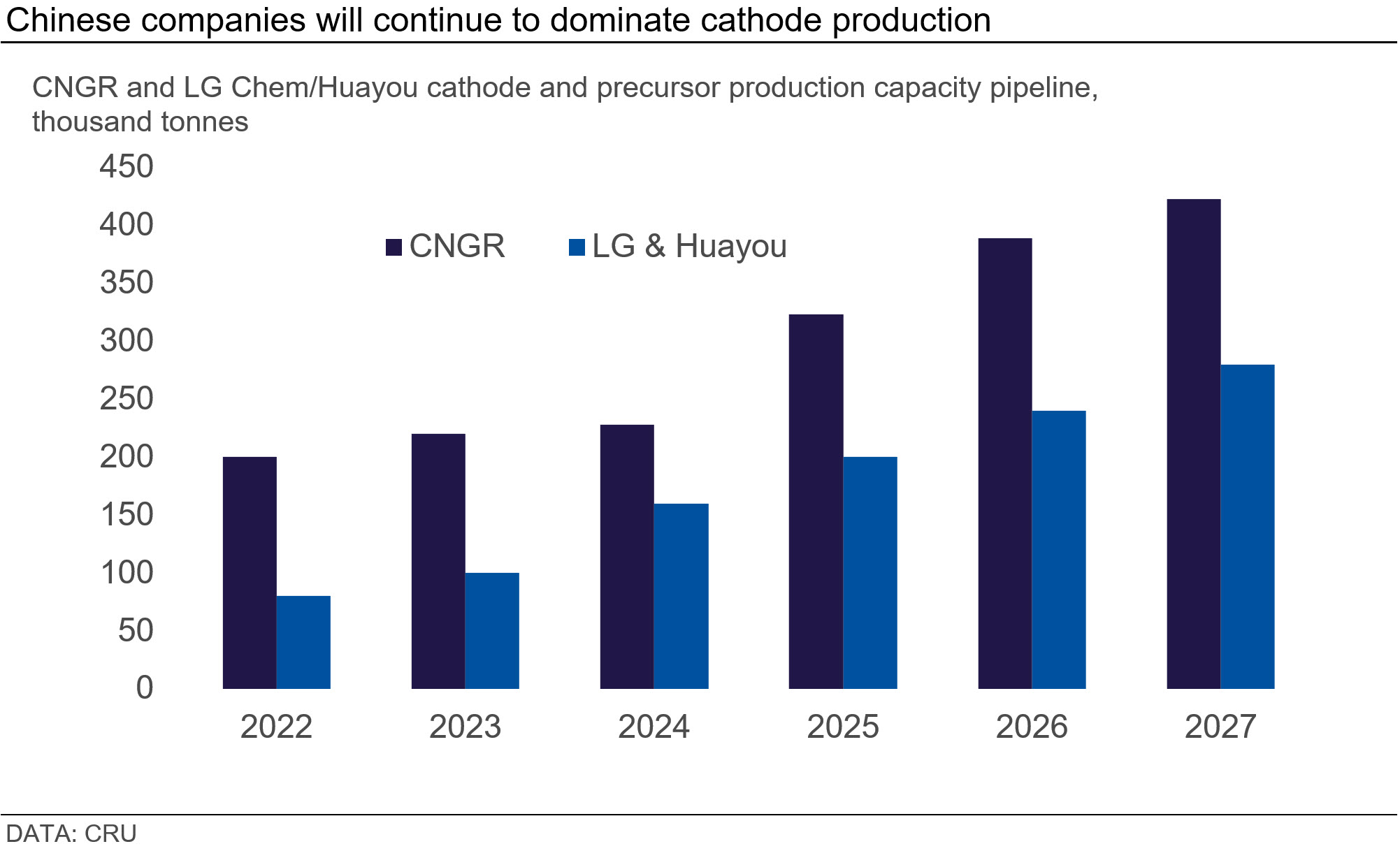

Given the company’s recent investment in mid-stream production, CNGR’s pipeline cathode and precursor capacity has risen to almost 800,000 t/y, according to CRU data.

Similarly, LG Chem and Huayou are planning on extending their influence in the North American and European battery market by setting up assets in Morocco. The planned LFP cathode plant will have a nameplate capacity of 50,000 t/y, enough material for 500,000 EVs, according to LG Chem. Production is expected to begin in 2026 and the location of the plant is yet to be publicly announced.

Meanwhile, the lithium refinery will produce up to 52,000 t/y of carbonate and hydroxide by 2025, providing feedstock for the cathode plant.

The project will not be the first time Huayou and LG Chem have collaborated, with two joint venture cathode plants operating in China and another under construction in South Korea. Notably, the companies also announced plans to build a precursor plant and a high-pressure acid leaching plant in Indonesia in late September.

Given the level of cooperation between LG Chem and Huayou, the companies have a pipeline cathode and precursor capacity of 360,000 t/y through their joint ventures with each other.

Morocco emerges as a battery supply chain hub

Morocco’s role as a hub for the battery and EV value chain continues to expand with investments such as these. There are various factors which make the country an ideal location to produce battery materials.

In addition to its proximity to the European market, less stringent regulations compared to North America and Europe facilitate faster plant construction. Public opposition, which could delay or halt construction, is also less likely to materialise.

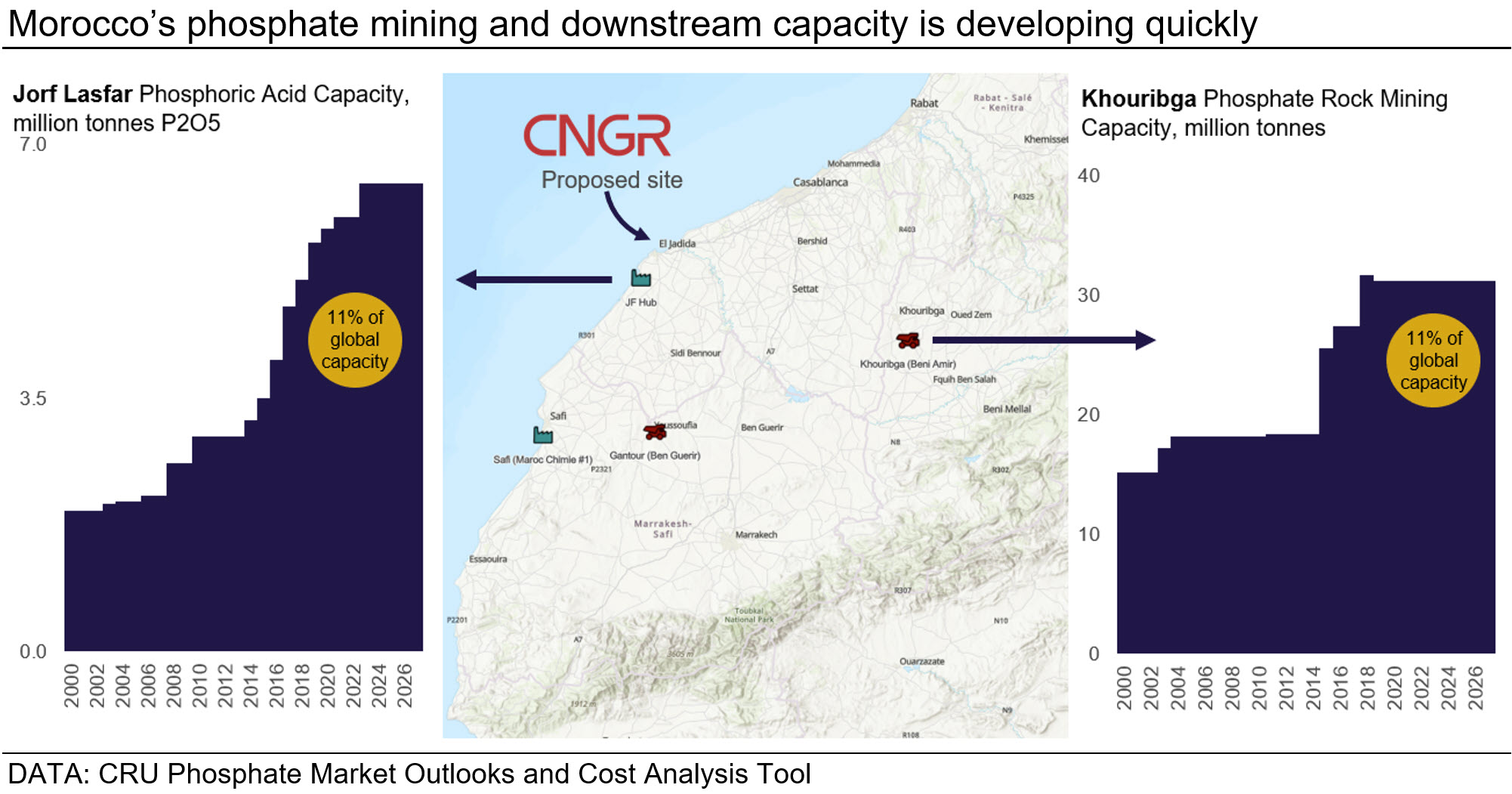

The country’s access to the raw materials required for battery production is another significant bonus. Morocco holds 70% of the world’s phosphate reserves. Phosphate producer, OCP, has significantly expanded its phosphoric acid and downstream production capacity at Jorf Lasfar over the past two decades.

The Jorf Lasfar site alone accounts for 11% of global phosphoric acid capacity and it is comfortably the lowest cost production facility in the world. This uses phosphate rock mined at Khouribga, which also accounts for 11% of global capacity. It has invested significant capital into state-of-the-art infrastructure since the launch of its industrial development plan in 2008, with $13 billion of green investment planned over 2023-2027. This investment plan includes objectives for OCP to reach 30,000 t of LFP intermediate products by 2027.

Morocco is also strategically positioned to import cobalt and lithium from other African countries. Given a significant level of investment from various industries, the country’s infrastructure is particularly strong, reducing logistical concerns.

Another major driving factor in Moroccan investment is the country’s trade agreements. Morocco has an advanced trade status with the EU, which covers industrial goods, a Free Trade Agreement (FTA) with the US, and it is part of the African Continental Free Trade Area (AfCFTA).

While the AfCFTA will facilitate the import of materials, the agreements with the US and the EU may be a huge benefit given recent trade legislation. Despite an underlying risk that Huayou and CNGR falling under the ‘foreign entity of concern’ designation in the US Inflation Reduction Act, the companies expect that the material they produce in Morocco will still contribute to IRA tax credit eligibility, given it will be produced in a FTA country.

It should be noted that phosphate fertilizer from Morocco has been subject to US countervailing duties since 2020, although these continue to be contested within US courts.

However, even if the battery material is not eligible for unrestricted trade into the US, the location of Morocco allows the destination of exports to easily be switched to other regions which are not hindered by government legislation.

CNGR, LG Chem, and Huayou’s investments are likely to be the tip of the iceberg. As legislation becomes more focused on protectionism and localised supply chains, more companies, particularly from China, will look to invest in Morocco.

Explore this topic with CRU

Author Cameron Hughes

Battery Market Analyst View profile

Contributor Sam Adham

Head of Battery Materials View profile